Wet Testing

When most people drive in the rain, they typically slow down and are more cautious. They could be either experiencing or trying to avoid hydroplaning, which is a term for when the vehicle becomes unstable on wet surfaces.

Hydroplaning is mainly caused by the tire, although the entire dynamics of the vehicle can affect its stability. The tire’s force generation is created through the stress and strain that develops in the contact patch from the interaction between the tire tread and the driving surface. When it is raining, water can get between the tire tread and the surface. The water also cools the tire. Both interactions can cause tire grip changes which may negatively affect the stability of the vehicle.

How much does the vehicle need to alter its path to be deemed unstable? Although there are multiple standards on how to quantify a tire’s performance on dry surfaces, there is only one standard to quantify the tire’s performance on wet surfaces, called the EU Wet Grip Label. This standard only quantifies the braking performance at 65kph, which can be well below normal operating range for the vehicle. Further, this procedure does not examine the lateral force generation of the tire or the speed effect of the tire in wet conditions. So the question becomes “Are measurements from the EU Wet Grip Label procedure or a vehicle test a good source for tire manufacturers to develop tread compounds or tread patterns?”

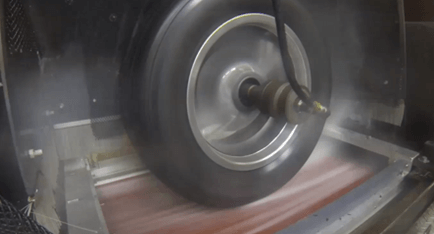

For many decades vehicle and tire manufactures have relied on indoor test equipment to quantify tire performance. So why do manufactures still use vehicle tests on outdoor test tracks to develop tires and vehicles for wet performance? These tests are typically performed by driving the vehicle in a constant circle at multiple speed increments while driving through a puddle of a known depth. The speed at which the vehicle becomes unstable is deemed the hydroplaning speed. But before reaching the unstable point, is the tire’s force generation capability changing at all? The utilization of the flat belt force and moment machine has identified load, pressure, and speed influence on the tire’s force generation for dry conditions.

At GCAPS, we have taken this same approach for understanding wet tire performance. GCAPS has developed a water delivery system that can apply a consistent water depth to the tire for speeds up to 250 kph. Using the water delivery system, we have developed procedures to not only determine a hydroplaning speed, but also how a tire performs for all conditions a vehicle may encounter on roads or racetracks. Our methodology can be used to determine the effect of tread compound and tread patterns through the entire operating speed. Using the flat belt force and moment equipment and water delivery system, the change in force generation is measured at various speeds, loads, cambers, pressures, and even water depth. These objective measurements are the required information for tire manufactures to make informed decisions on the benefit of tread patterns and tread compounds for wet performance. The EU Wet Grip procedure can also be performed with GCAPS system. This research along with speed comparisons of the Wet Grip labels values were presented at the 2020 TTX expo by Kenneth Erdner.

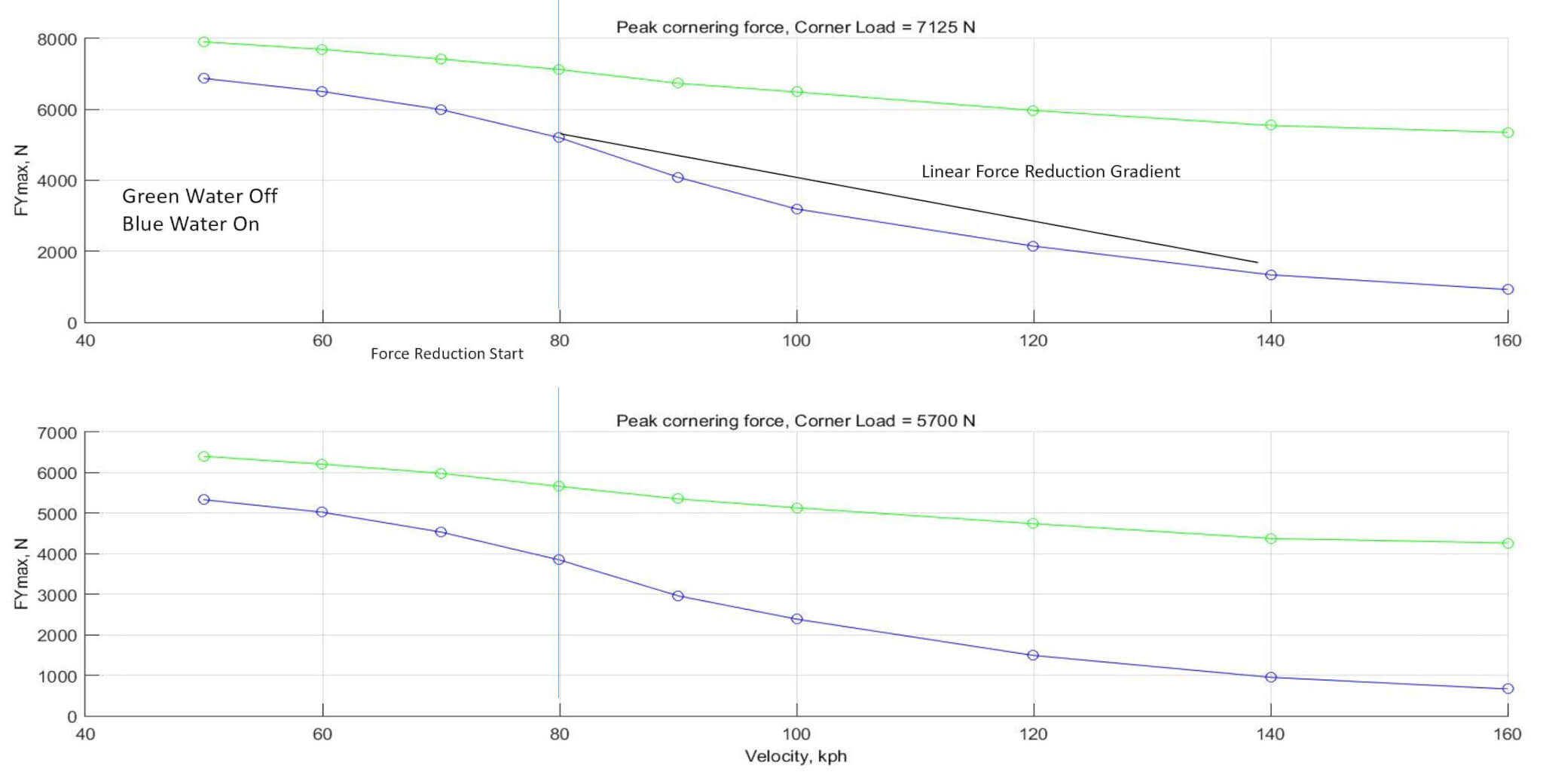

GCAPS wet test methodology provides the objective data for lateral, longitudinal, and combined tire responses for various water depths. The methodology starts with creating a baseline performance in dry conditions. This establishes how the tire performance changes due to speed, load, or other inputs. It also establishes the force response on the indoor surface. These same conditions are then repeated with varying levels of water depth. The water depth ranges from just a mist to multiple millimeters. The tires temperature will change from the cooling effect of the mist without introducing water between the tire and the surface. This helps separate the tread compound performance from the tread pattern performance. To examine the tread pattern performance, a speed increment test is performed. The change in lateral force response from the baseline dry conditions is used to determine which speed the force generation starts to change. The tread pattern’s effectiveness of evacuating water from the contact patch can be examined by the different speeds the force reduction starts and the gradient of reduction after the initial reduction. This is an example of the test methodology for lateral force.

This methodology has been used by tire manufacturers to improve tread patterns, tread compounds, and wear impact for passenger car and motorsport tires. The ability to control and measure the forces, moments, and positions accurately in various wet conditions is also used to create tire models for chassis controls development.

With the GCAPS water delivery system and premier flat belt force and moment equipment, we can help improve tire performance and thus vehicle performance. Contact GCAPS to move your wet performance tests from outdoor vehicle methods to a proven, reliable, and consistent indoor methodology.